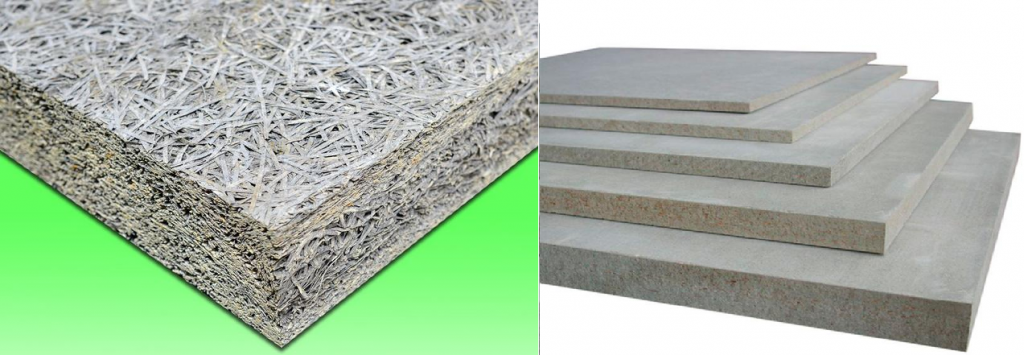

Cement Chipboard vs Wood Wool Cement Board

Basic components of the cement chipboard are cement and wood powder with fibre. Wood wool cement board is a mixture of cement, long-fibre wood wool and sodium silicate. Both types of boards are manufactured under pressure and at high temperatures to form unique properties.

Basic components of the cement chipboard are cement and wood powder with fibre. Wood wool cement board is a mixture of cement, long-fibre wood wool and sodium silicate. Both types of boards are manufactured under pressure and at high temperatures to form unique properties.

The most most valuable property of the boards is FIRE SAFETY.

The range of applications of the cement chipboards and wood wool cement boards is huge. They are a basis for facades and roofs. They are used to finish walls, floors and partitions and installed as formwork for foundations and basements. Finally, the cement chipboards and wood wool cement boards are used for cladding barns, hen houses, farms, vegetable storehouses, other agricultural buildings, dog houses, kennels, etc. You can also safely use CCB and WWCB in construction of inspection pits in garages and car repair centres.

Owing to their NONFLAMMABILITY and GOOD ECOLOGICAL PROPERTIES, both types of the boards are certified for all types of residential and industrial buildings such as schools, offices, kindergartens, hospitals, cottages, houses, flats, warehouses, etc. The unique qualities of the wood wool cement boards and cement chipboards have been proven by our customers. In the end, let's look into key differences of the boards.

CCB is denser and heavier, so it is preferred for facades. CCB is the best for underfloor heating due to its high thermal conductivity. Ceramic tiles, PVC tiles and ceramic granite can be glued securely to such boards.

The wood wool cement board has other advantages such as good soundproofing and heat insulation properties which are highly appreciated by our customers who construct walls and partitions both in houses and apartments.

WWCB is a sound floor base for laminate, parquet or PVC tiles.

Wood wool is made of low-value timber using special machines.

Wood wool cement specifications:

| Parameter | Heat insulation boards | Structural boards |

| Density, kg/m3 | 300… 400 | 500 и более |

| Thermal conductivity X, W/(m°K) | 0,09…0,12 | 0,12…0,15 |

| Compressive strength RmnMPa | 0,4…0,7 | 1,2…4,0 |

| Compressive strength class | В 0,35…В 0,75 | В1; В 1,5; В2,5; В3,5 |

| Frost resistance, cycles | Не менее 15 | Более 15 |

| Water absorption, % | Не более 60 | Не более 60 |

Specifications of cement particle board:

| Parameter | DSP |

| Modulus of elasticity in bending, MPa | 4500 |

| Hardness, MPa | 45 — 65 |

| Thermal conductivity, W/(m0C) | 0,26 |

| Specific heat capacity, kJ/(kg0С) | 1,15 |

| Specific resistance to pulling screws out of the sheet, N/m | 4 — 7 |

| Biological stability class | 4 |

| Frost resistance: | |

| — число циклов переменного замораживания/оттаивания без видимых признаков разрушения | 50 |

| — остаточная прочность, % | 90 |

| Resistance to cyclic temperature and humidity changes: | |

| — снижение прочности при после 20 циклов температурно-влажностных воздействий, % | 30 |

| thickness swelling, field 20 cycles of temperature and humidity effects, % | 5 |

The use of fiberboard slabs in the construction of a country house:

· To create fixed formwork;

For soundproofing and insulation of walls, floors and ceilings - the slab absorbs sounds in some structures better than drywall and retains heat well due to the porous structure.